Single Use Plastics in Mushroom Cultivation

Before you start exploring this blog, I am assuming that all of you are familiar with the basics of what mushrooms are and how they are cultivated. If you’re new to this, please check out these blogs to know more about mushroom cultivation and the jargon used:

- Lifecycle of a Mushroom

- Glossary | All things Fungi

- 3 tips for the Best Oyster Mushroom Growing Experience

Mushroom cultivation by its very nature is sustainable and has a positive impact on the environment. Just by cultivating mushrooms, we upcycle a lot of agricultural waste which would have otherwise been disposed of or burnt. Mushrooms also use only a fraction of water used by commercially cultivated crops.

What makes things better? The substrate leftover after growing mushrooms is a really good compost starter!

If you want to explore the positive environmental impact of mushroom cultivation then this blog is for you: Why India Needs More Mushroom Farmers: Environment

But all things said, the resting guilt most mushroom cultivators face, is the usage of single-use plastics. In this blog, we are going to look deeply at the use of plastics in the mushroom industry, viable alternatives, and advancements in the field of biopolymers that may be possible solutions.

To begin with – let’s get down to basics.

Why does one need to use plastics in mushroom cultivation in the first place?

Here are the 5 main uses for plastics in the mushroom cultivation process:

- Prevent evaporation: Most of the commonly cultivated mushrooms are composed of ~80% water. This water is absorbed by the mushroom from the sterilized or pasteurized substrate which is hydrated to hold 55 – 70% water, as a percentage of the total weight of the substrate. The plastic acts as a physical barrier to ensure that the water present in the substrate doesn’t get lost due to evaporation.

- Protect against contamination: Plastic is inorganic. It lacks the nutrition and hence doesn’t support the growth of any unwanted microorganisms that can negatively affect the growth of mycelium.

- Keep pests out: Plastic acts as a physical barrier to stop pests from entering and eating up or contaminating your substrate.

- Protect against physical damage: The plastic cover ensures that the loose substrate stays intact while it is being moved around and while the mycelium slowly spreads through the substrate making it one single mass.

- Provide suitable microclimate: Certain mushrooms like Antler Reishi (shown in the picture below), King Oyster & Enoki need a specific microclimate (high in C02 for example) to grow a certain way, the plastic helps in maintaining certain cultivation parameters.

Are there ways to grow mushrooms without using plastic?

Now that we’ve established the uses of plastic, another important question we need to address before we proceed is, are there any established methods of cultivating mushrooms without the use of plastics? Yes! there are plastic-free ways to grow mushrooms, the most common methods being log/totem cultivation and bed cultivation. In log/totem cultivation, logs of suitable trees and the right dimensions are inoculated with mycelium. The mycelium then feeds on the log and colonizes it, giving out mushrooms when the weather is right. Many mushrooms such as Shiitake, Oyster, and Reishi can be grown outdoors using logs.

The major disadvantage with this method is that the cultivator has to wait a year or two before his first harvest and also the fact that harvests will be seasonal, making it hard to cultivate mushrooms throughout the year.

Finding the right wood, at the right time of the year and in the required dimension can be hard. Another challenge with logs is that they are heavy, moving and handling them can be very energy-intensive. Apart from logs, outdoor beds are also a great way to grow mushrooms without the use of plastics. In this method, the cultivator makes an outdoor bed using a pasteurized substrate that has been layered with spawn. One major drawback of this method is that the number of species that can be cultivated is very low, for example, Paddy Straw, Wine Caps, and certain species of oyster mushrooms.

Growing in beds can also lead to increased chances of contamination and attacks by pests. Both methods described above are still used in different parts of the world today and can be viable for the cultivator depending on his location and requirements but for a cultivator looking for consistent yields and year-round production, bag cultivation remains the most practical option.

Let’s dig a little deeper and understand what are the different types of plastic available in the market and which ones are suitable for growing mushrooms.

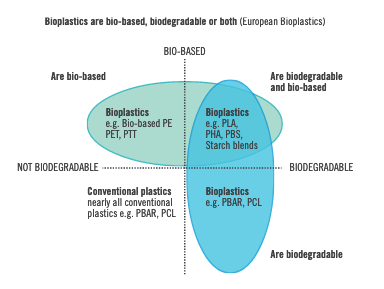

Based on what they are made of and how they degrade, plastics can be put in one of 4 categories:

- Bio-based and Biodegradable: These plastics are derived from natural sources and are biodegradable. Eg: PLA, PHA, PBS, Starch blends, etc

- Non-bio-based and Biodegradable: These plastics are derived from artificial sources and are biodegradable. Eg: PBAR, PCL, etc.

- Biobased and non-biodegradable: These plastics are derived from natural sources but are not biodegradable. Eg: Bio-based PET, PE, PTT, etc

- Non-bio-based and non-biodegradable: These plastics are derived from artificial sources and are not biodegradable. Nearly all conventional plastics fall into this category.

This categorization makes it very clear that just because something is made from a natural source doesn’t mean that it is automatically biodegradable and on the other hand just because something is made artificially it doesn’t necessarily have to be biodegradable. Another common mistake is thinking that compostable and biodegradable imply that if you simply throw away that piece of plastic, it will degrade by itself. This is incorrect, the words “compostable” and “biodegradable” imply that it can be composted or degraded under industrial conditions for composting or bio-degradation!

This brings us to our next question, what is the most suitable type of plastic available for mushroom cultivation and why?

Most cultivators prefer using Polypropylene number 5 or PP5 for short. PP5 is commonly used as packaging for foodstuffs and as containers for food as it is a very safe and stable polymer that doesn’t degrade easily. It is the safety coupled with the fact that it can withstand temperatures of 121 degrees and 15 PSI pressure with ease, (this temperature and pressure are encountered in an autoclave which is typically used to sterilize substrate bags) that makes polypropylene bags for mushroom cultivation most popular. Unlike PP5, biodegradable polymers such as PLA, PHA, etc. cannot withstand such high temperatures or pressure and have poor barrier properties. This makes these biodegradable mushroom bags unsuitable for mushroom cultivation commercially.

This being said, if you’re pasteurizing your substrate and can find a way for the substrate to retain moisture, you can try using biodegradable polymers available in the market for mushroom cultivation. Post use, they need to be sent to the right facility to be composted. There are scientific papers out there that have examined the ability of certain plastic eating mushrooms (some oyster mushroom species for example) to degrade bioplastics such as PLA. Keeping this in mind, please be sure that you are using a type of bioplastic which the mushroom mycelium cannot degrade! To know more about this please read this article.

A few materials that we often get asked about for mushroom cultivation are jute bags and clay/ceramic pots. Both of these aren’t viable alternatives to plastic. Jute bags are porous, so evaporation will not be controlled and since it is made from plant matter they can get contaminated very easily. As for earthen pots, they are full of micropores which can act as a surface to attract contaminants, and similar to jute, the porous nature of the material will result in a loss of moisture from the substrate. Apart from this, clay/ceramic pots are fragile and heavy, handling them without damage can become an issue if they are used at a commercial level.

Though plastics are bad for the environment, there is no denying that it is a really good material that has a lot of uses and is economically viable for mushroom cultivation. One viable alternative that a mushroom cultivator can try is growing mushrooms in containers. These reusable PP5 containers have a long life and can be used over multiple cycles without any need to be replaced. Mind you, this alternative may not be suitable for all varieties of mushrooms and there will be an additional step of cleaning and maintaining these buckets, which will need additional resources. For example: Growing King Oyster mushrooms in buckets will not work the same way as other oyster mushrooms because King Oysters grow vertically from the top as compared to other oyster mushrooms which grow from the sides. For that matter growing Shiitake mushrooms in buckets is not a good idea either since the blocks need to be removed from the buckets to initiate fruiting.

Here are some representations of the same: Enoki mushrooms and King Oyster mushrooms being cultivated in reusable mushroom growing containers:

While writing this I am hopeful about the future and I feel that it is just a matter of time before performance-based bio-materials become widely available and cost-effective enough to replace plastics altogether in the mushroom cultivation process. Mushroom cultivators around the world are rooting for the day when biodegradable mushroom bags for cultivation will become widely available. We might even have completely sustainable and biodegradable mushroom plastic or mycelium based plastic alternatives which can be used for mushroom cultivation in the future. Till then, let’s all be on the hunt for more sustainable materials and practices, and let’s all do our bit in growing the mycelium network!

Jashid is the co-founder of Nuvedo. An IIM graduate, with a bachelors in manufacturing engineering from BITS Pilani, his interest with fungi and mushrooms started with looking for alternate sources of vegetarian protein. He loves talking about mushrooms, spending time with them and studying their behavior in all shapes and forms. The role of fungi in the natural ecosystem, with mushrooms being at the forefront, led him to explore their structures, benefits and cultivation. Bringing his experience in retail and sustainability together, through a lens of permaculture, he cofounded Nuvedo with the aim of bringing legitimate, gourmet, and medicinal mushrooms to Indian people. He is committed towards spreading the nutritive and therapeutic properties of mushrooms while building an ecosystem of trust with the community. His love for people and passion for mushrooms has evoked the birth of this organization.

Jashid is the co-founder of Nuvedo. An IIM graduate, with a bachelors in manufacturing engineering from BITS Pilani, his interest with fungi and mushrooms started with looking for alternate sources of vegetarian protein. He loves talking about mushrooms, spending time with them and studying their behavior in all shapes and forms. The role of fungi in the natural ecosystem, with mushrooms being at the forefront, led him to explore their structures, benefits and cultivation. Bringing his experience in retail and sustainability together, through a lens of permaculture, he cofounded Nuvedo with the aim of bringing legitimate, gourmet, and medicinal mushrooms to Indian people. He is committed towards spreading the nutritive and therapeutic properties of mushrooms while building an ecosystem of trust with the community. His love for people and passion for mushrooms has evoked the birth of this organization.